Experience Curve What is it? Definition, Examples and More

They begin resisting change, which may eliminate their cost benefits of the experience curve. Competitors that replicate the strategies and adopt the latest technologies will easily surpass the market leaders and achieve their own experience curve. Boston Consulting Group defined the relationship as “experience curve,” where a company gains more experience by producing more of a particular product. Additional research conducted by BCG in the late 1960s and early 1970s revealed that the experience curve effect for various industries ranged between 10% and 25%. A learning curve is measured and calculated by determining the amount of time it will take to perform a task.

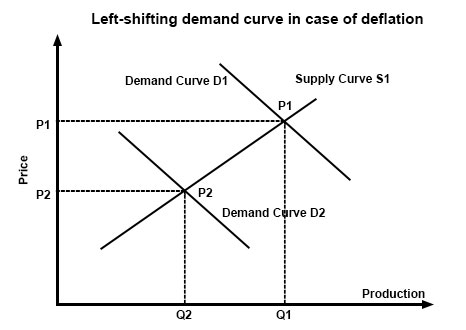

The concept is used in business to estimate reductions in labor costs as unit volumes rise, so that higher production volumes result in lower labor costs per unit. This gives them a significant cost advantage, which can help them to compete more effectively. Organizations can take advantage of this concept by analyzing their own costs, and seeking to increase production volume in order to achieve lower unit costs. The experience curve is typically represented graphically as a downward-sloping curve, with the unit cost on the vertical axis and the accumulated volume of production on the horizontal axis. The slope of the curve reflects the rate at which unit costs decrease as production volume increases. The Experience Curve argues that the more experience a business has in manufacturing a product, the more it can lower costs.

Origin of the Experience Curve

A high learning curve indicates to a business that something might require intensive training, but that an employee will quickly become more proficient over time. Experience curve is a graphical representation of the relationship between the cost of production and the experience the company… Learning by doing describes the process with which workers and firms learn about the process of production as more is produced. As learning deepened, the efficiency of production will generally improves as well. The vertical axis of a learning curve represents the rate of learning, while the horizontal axis represents the volume or duration of experience.

In essence the theory goes, for every doubling in global installed capacity or sales, there is a corresponding reduction in costs which is remarkably consistent for a given technology over successive doublings. Because learning curve data easily creates trend lines, it’s fairly common to see learning curve data depicted graphically. There are several data points to choose from, one of which is the total cumulative time needed to produce a given number of tasks or units. In the graph below, the learning curve shows that more time is needed to generate more tasks. This means that every time we double the cumulative quantity, the process becomes 20% more efficient. Part of the explanation for this discrepancy was that different products provided different opportunities to gain experience.

Further experience curve examples

The value-added costs include the cost of manufacturing, marketing, distribution, and administration. However, the graph above fails to demonstrate how the process is becoming more efficient. Because of the graph’s upward slowing curve, it appears it takes incrementally more time to perform more tasks. However, due to the nature of the learning curve, the x-axis is doubling and incrementally taking less time per unit. For example, consider the graph below that demonstrates the approximate average time needed to perform a given number of tasks. Experience curves are also known as technology learning and in some literature as ‘learning-by-doing’.

However, the 960 hours in the next row is the time it took to yield two additional tasks. There is no fundamental economic law that can predict the existence of the experience curve, even though it has been shown to apply to industries across the board. And if it is true in service industries such as investment banking or legal advice, the lower costs are clearly not passed on to customers.

Additional Resources

A company that benefits from the effects of an experience curve enjoys several advantages over its competitors. As the business grows and lowers its unit production costs, it will gain a bigger market share over its rivals. It means that it will control a bigger portion of the market, increasing its profit potential.

For example, the learning curve can play a fundamental part in understanding production costs and cost per unit. As the employee becomes more proficient at their job, they will be able to manufacture more goods in a smaller amount of time (all else being equal). In this example, a 90% learning curve would mean there is a 10% improvement every time the number of repetitions doubles.

This is a detriment to market entry as the firm can lower its price, which may further increase its market share and place added pressure on potential competitors, as found in a study by Lieberman. Learning through experience becomes an important component of the increased market share strategy. Experience curve refers to a diagrammatic representation of the inverse relationship between the total value-added costs of a product and the company experience in manufacturing and marketing it.

DIRECT LABOR HOURS MODEL.

When Texas Instruments entered the market and implemented the strategy in 1972, calculator unit costs dropped from a number in the thousands to under $10 in around a decade. During the early 1970s, advances in hand-held calculator technology and sizeable price-sensitive demand provided an ideal opportunity for the company to adopt an experience curve strategy. They found that the value-added production cost declined by as much as 20 to 30% each time the total manufacturing output doubled.

- For example, the 600 hours of incremental time for task No. 2 is the time it took to yield one additional task.

- With the benefit of 11 years of assembly experience, Ford cut production costs of the Model T and increased its market share from 10% to 55%.

- March states that managers of competitive organizations often find themselves in situations where relative position with regard to a competitor matters.

- Internal applications include developing labor standards, scheduling, budgeting, and make-or-buy decisions.

- The unit cost of production includes the cost incurred by the company to add value to the product but excludes the cost of purchasing the materials.

- The experience curve is typically represented graphically as a downward-sloping curve, with the unit cost on the vertical axis and the accumulated volume of production on the horizontal axis.

Experience curve is the systematic reductions in the production costs that occur over life of a product. In fact, the reduced exploration risk of ESG projects enabled a manufacturing approach to project development where scale, learning, and innovation factors eventually resulted in impressive cost and efficiency improvements. This output then decreased manufacturing costs further, which caused calculator prices to decrease and demand to increase in a positive feedback loop. Once the company was able to lower prices, the additional demand accelerated progress along the curve and enabled TI to rapidly increase output. In response, pent-up demand caused sales to skyrocket and, since the company was an experienced-based cost leader, its competitive advantage was impossible to overcome. This potentially shortens the learning curve and fast tracks their ability to reduce costs with experience.

More Resources

On the downside, the experience curve can sometimes come to an abrupt end when the competitors discover the strategy and replicate the cost reductions without making huge capital investments to gain experience. The experience curve can also come to an end when new technologies are introduced, and the company will need to create a new curve. It must upgrade its processes by replacing the old experience curve with a new one that allows it to retain its competitive advantage.

9 best animation software for captivating videos – Robotics and Automation News

9 best animation software for captivating videos.

Posted: Wed, 09 Aug 2023 15:33:10 GMT [source]

Even when BCG first expounded the relationship, it had been known since the second world war that it applied to direct labour costs. Less labour was needed for a given output depending on the experience of that labour. In aircraft production, for instance, labour input decreased by some 10–15% for every doubling of that labour’s experience.

By 2010, however, the percentage of oil and gas wells that were drilled dry had dramatically reduced to just 10%. Contact lens maker Bausch & Lomb consolidated their market position by computerizing lens design and expanding their plant to facilitate greater productivity. This article is adapted from “The Economist Guide to Management experience curve is also known as Ideas and Gurus”, by Tim Hindle (Profile Books; 322 pages; £20). The guide has the low-down on over 100 of the most influential business-management ideas and more than 50 of the world’s most influential management thinkers. Access and download collection of free Templates to help power your productivity and performance.

With more time, streamlined processes are fed into technology, further increasing the level of experience that a business has in manufacturing a product. Both concepts are intertwined, and it is difficult to differentiate between experience and increased level of production. But in favorable markets characterized by expensive electricity and an established carbon market, the experience curve would allow new ESG projects to become cost competitive in just a few iterations. They can be represented in a chart, with linear coordinates, like the charts above in which the shape is an actual curve. A learning curve can also be depicted between axis points in a chart as a straight line or a band of points. B) As a company produces more and more units of a new product it costs less per unit to manufacture.